High refractive index (RI) materials are used for diffractive optical elements (DOEs) employed in augmented, virtual, and mixed reality (AR/VR/MR) devices and optical sensors. One cost-effective approach for DOEs with high RI is to use a resin that can be processed rapidly by photo nano-imprint lithography (P-NIL) methods. When the RI exceeds 1.7 at 589 nm, injection molding is no longer possible due to the lack of very high RI thermoplastics, and P-NIL becomes the overwhelming method of choice for fabrication of elements with nano scale features. ACW has been a leader in developing resins for P-NIL since the methodology was referred to as 2P (for photo polymer) and used for information layers in data storage applications including Blu-Ray discs.

ACW offers a range of P-NIL resins including several that give high RI cured films. IP-158 and PR-1600-CA with cured films’ RI at 25 °C of 1.58 and 1.60, respectively, have been marketed for more than a decade. More recently, ACW developed a higher RI P-NIL resin, PR-1612, which gives a cured film with RI = 1.612 at 589 nm. And, in 2022, ACW introduced the LuxNIL® line of very high RI resins with tunable RI ranging from 1.6 to 1.8 at 589 nm allowing index-matching with the underlying high RI glass.

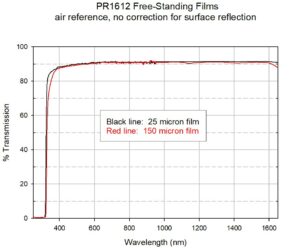

The high RI resins IP-158, PR-1600-CA, and PR-1612 are solvent free and can be used for relatively thick films. These materials are optically clear as can be seen in the UV-vis-Near IR spectra of a 150 micron thick PR 1612 film. The only loss of light for this film is from surface reflections. And these materials are quite robust surviving both 85 °C/85% RH for 1,000 hours and 1,000 thermal shock cycles of -40 °C/150 °C with very little effect. For more information on these high RI resins, click HERE to see a brochure.

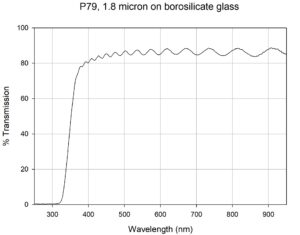

The LuxNIL® very high RI resins are inorganic/organic hybrids containing PGMEA solvent. They were developed specifically for thin films (100 nm to 3 microns) required for AR/VR/MR applications. These films have high transmittance and clarity and exceptionally low haze as demonstrated below for LuxNIL® P79. For more information on the LuxNIL® resins, click HERE to see a brochure.

ACW High and Very High RI P-NIL Resins

| Resin | η25°C (cps) | RI589nm | Data Sheet |

| IP-158 | 450 | 1.584 | TDS |

| PR-1600-CA | 400 | 1.600 | TDS |

| PR-1612 | 1,800 | 1.612 | TDS |

| LuxNIL® P65 | 3 – 5 | 1.65 | |

| LuxNIL® P73 | 3 – 5 | 1.73 | |

| LuxNIL® P79 | 3 – 5 | 1.79 |