Active Alignment Adhesives

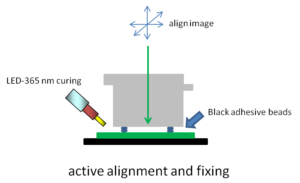

Active alignment adhesives are used for precise, computer-controlled alignment in camera, sensor, optical, and optoelectronics components as illustrated below. The adhesive is dispensed, the components are mated and then aligned with computer control, and the adhesive is set by UV curing.

If light can be transmitted to the entire bonding region, then UV cure adhesives can be used. Quite often, however, the components have shaded regions, which requires dual-cure adhesives, a portion of which is cured by UV and the remainder of which is cured by heat.

ACW provides 100% epoxy, high Tg UV-Cure and Dual-Cure (UV and/or heat) adhesives for active alignment applications. These “epoxy only” adhesives provide superior bond strength and environmental performance, and the high Tg ensures that no motion occurs during thermal cycling. The table below lists some of the most popular active alignment adhesives. Note that Dual-Cure epoxy adhesives (Dual Cure Adhesives page) have both low temperature range (80-100 °C) for temperature sensitive components and high temperature range (130-150 °C) for superior bonding.

The adhesives in the table have the following features.

A, UV-cure; B Dual-Cure (UV or heat); C Fiber to V-groove; D lid and lens bonding; E chip packaging; F active alignment; G High UV depth of cure; H thermal conductive; I underfill.

| Epoxy | Feature | η (cps)* | TI** | Tg (°C) | Data |

| A535-AN | A C D | 4,000 | – | 170 | TDS |

| A539-DM | B C E | 2,000 | – | 145 | TDS |

| A1853-TX | B F | 65,000 | 7 | 165 | TDS |

| A1855-TX | B F G | 65,000 | 7 | 180 | TDS |

| A1858-TX | B F | 27,000 | 4 | 160 | TDS |

| A1867-TX | B F | 12,000 | 2 | 160 | TDS |

| A1708-TX | B F | 13,000 | 2 | 168 | TDS |

| TCR-1003R1 | B G H I | 10,000 | 2 | 166 | TDS |

*Viscosity at 25 °C; for thixotropic resins, η is at 10 s-1 shear rate.

**Thixotropic Index = η at shear 1 s-1 / η at shear 10 s-1.

Click on the image to open a PDF table on a new page.