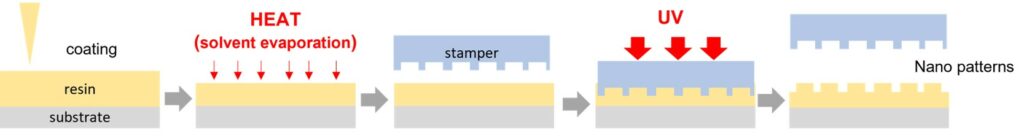

High refractive index (RI) materials are employed for production of quality diffractive optical elements (DOE) used in augmented, virtual, and mixed reality (AR/VR/MR) devices and a variety of optical sensors. Higher RI DOEs provide wider fields of view (FOV), and low-cost mass production of DOEs with RIs greater than 1.7 can be accomplished using photo nano-imprint lithography (P-NIL). In this process a fluidic high RI resin on a wafer is imprinted with a master and cured with UV light to give a wafer embossed with nano patterns that is subsequently diced. In principle, multi-stack assemblies can be fabricated before the dicing.

The components for high RI P-NIL fabrication are high RI glasses and high RI resins, potentially matched in RI to prevent internal reflection. Addison Clear Wave now offers very high RI LuxNIL® resins that can be tuned to RIs between 1.70 and 1.96 at 589 nm. LuxNIL® films display high transmittance and clarity and very low haze. Moreover, these films are robust, surviving extended exposure to 85 °C and 85% RH with no cracking or delamination from glass and little change in optical properties. For an informational brochure on LuxNIL® resins click HERE.

To download a joint ACW – EV Group White Paper describing SmartNIL® applications of LuxNIL® resins with high resolution and sub-nm height gain per imprint, click HERE.

Contact us at LuxNIL@addisoncw.com to discuss LuxNIL® in your devices.