ACW provides a variety of epoxy-only UV-cure and Dual-Cure (UV and heat) adhesives for use in optoelectronics applications. We were asked to demonstrate that one of our popular Dual Cure adhesives, A539-DM, could be used in the light path for 1,310 nm light under extreme conditions. Specifically, we were asked to show that A539-DM had no optical degradation at 1,310 nm when heated at 150 °C for 1,000 hours. A pundit in our lab noted that, using the rule of thumb that a reaction doubles in rate for every 10 °C increase in temperature, 1,000 hours at 150 °C was about equivalent to a millennium at room temperature.

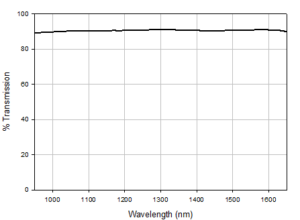

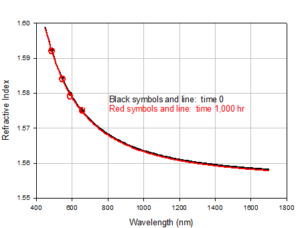

In our tests, we placed 40 micron thick strips of cured A539-DM between glass plates and heated these in a 150 °C oven. At several times, a strip was removed from the oven, and the Near IR spectrum was recorded. The RI at 1,310 nm also was determined by measuring the RI at four wavelengths in the visible, solving a Sellmeier Equation for RI, and extrapolating to 1,310 nm.

The figures below show the results after 1,000 hours at 150 °C. A539-DM passed this test with flying colors. If you are looking for highly robust UV-cure or Dual Cure adhesives, contact us at info@addisoncw.com with your requirements. See the data sheet for A539-DM HERE. See the section on Dual-Cure Epoxy Adhesives HERE.

Figure 1. Near IR spectrum of A539-DM film (40 micron) after heating at 150 °C for 1,000 hours. The reference for the spectrum is air. Surface reflection is 9-10%.

Figure 2. Sellmeier plots for A539-DM at time zero and after heating at 150 °C for 1000 hours. The RI at 1310 nm at time zero was 1.560, and the RI at 1310 nm after 1000 hours also was 1.560.