Thermally conductive epoxy adhesives are important in semiconductor packaging applications because they can provide both bonding strength and thermal conduction from the device to a thermal sink. Thermally conductive epoxies are either electrically conductive, containing a metal filler, or electrically insulating, containing a ceramic filler.

ACW offers thermally conductive electrically insulating dual cure epoxy adhesives containing boron nitride fillers. Both flowing and non-flowing versions versions are available; the choice is determined by the details of the fabrication. If the device is mounted on a PCB board after the adhesive is applied, a non-flowing, highly thixotropic adhesive is desired. If the device is assembled before the adhesive is applied, a flowing material is needed so that it can wick into a narrow gap by capillary action.

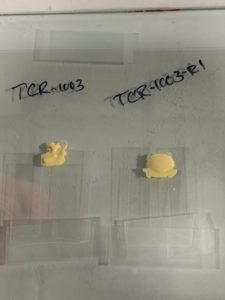

The pictures below illustrate the difference in character between flowing and non-flowing thermally conductive adhesives. TCR-1003 is a highly thixotropic material, whereas TCR-1003-R1 has the same composition with the exception that the thixotropic agent is omitted. The first photo shows the flow characteristics five minutes after the two adhesives were placed are on a vertical sheet of PET. In the second photo, the two adhesives were allowed to wick into a 125 micron gap for five minutes. In both cases, thixotropic TCR-1003 was stationary, but the non-thixotropic TCR-1003-R1 flowed by gravity or capillary action.