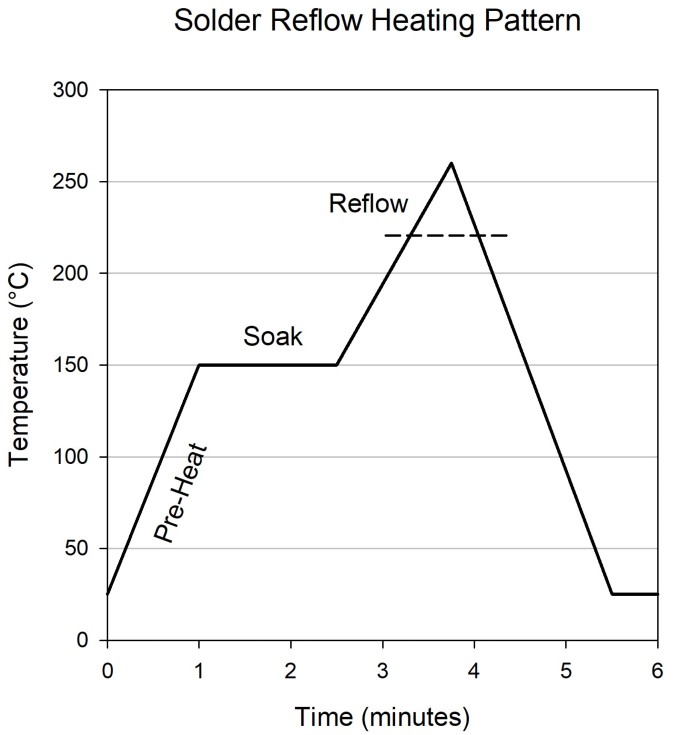

Those working with semiconductors are familiar with solder reflow conditions. A PCB containing solder and flux is heated to ca. 150 °C (pre-heat), held there for 1-2 minutes (soak), heated to ca. 260 °C, then cooled.

As devices are miniaturized, physical clamps holding and aligning components are increasingly replaced with adhesives. But solder reflow conditions severely test adhesives, especially when the adhesives were used to align optical components where micron level displacements would result in unacceptable dB loss.

For practical manufacturing purposes, adhesives used in semiconductor and silicon photonics assemblies should be UV-curable; using light to fix the adhesives permits rapid assembly and allows active alignment of optical components. For practical environmental purposes, the adhesives should be epoxies, which are more robust than most other types of adhesives.

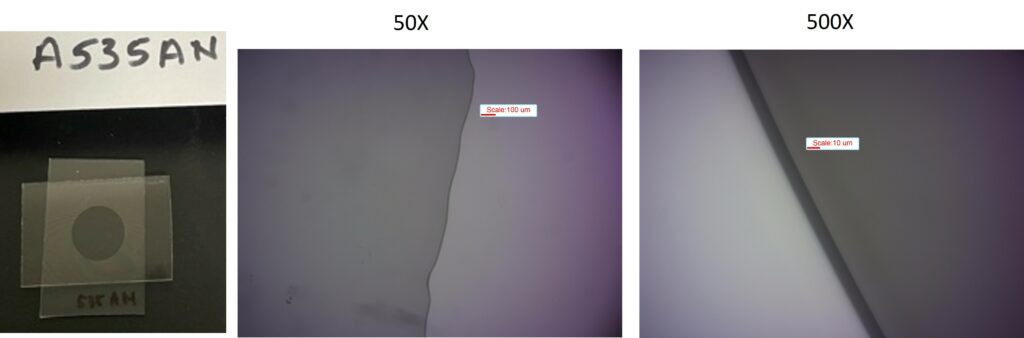

ACW offers the A535 family of UV-cured epoxy adhesives for the stringent demands of semiconductor and silicon photonics manufacturing. As an illustration of the stability of these adhesives, the behavior of A535-AN under simulated solder reflow conditions is shown below. The pictures are for 10-15 micron thick epoxy bonding two pieces of Borofloat® (®Schott Glass). Curing was 10 J/cm² of 365 nm UV (LED) followed by a thermal post-cure of 70 °C for 1 hour. The samples were then heated to 260 °C and held at that temperature for 10 minutes before cooling (fast ramp up and fast ramp down). There is no indication of detachment in the bulk or at the edges of the adhesive, even at 500X magnification.

The table lists several members of the A535 family. A535-AT and A539-DM are Dual Cure epoxy adhesives that can be cured by UV or heat and were designed for applications with shaded regions.

| Adhesive | η* (cps) | Tg (°C) | Curing | Data |

| A535-A | 1,100 | 145 | UV Cure | TDS |

| A535-AN | 3,000 | 165 | UV Cure | TDS |

| A535-AT | 1,200 | 160 | UV and/or heat | TDS |

| A535-AN-TX | thixo** 12,000 | 165 | UV Cure | TDS |

| A539-DM | 2,000 | 145 | UV and/or heat | TDS |

| A586 | 5,000 | 110 | UV Cure | TDS |

*Viscosity at 25 °C. **Thixotropic; the viscosity is for a shear rate of 10/s.