Are you assembling temperature-sensitive components with shaded regions? If so, your choices of adhesives are limited. For your demanding applications, ACW offers UV-Snap Cure epoxies, adhesives developed for optoelectronics, electronics and semi-conductor packaging where the parts are opaque or have shaded areas and the components are temperature sensitive.

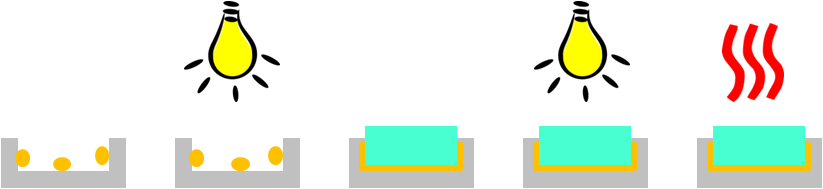

UV-Snaps are one-component epoxies that are room temperature stable as received. Their processing cycle is shown below. After dispensing, the UV-Snap is activated by a short burst of UV light. The activated adhesive cures evenly (i.e. no skin forms at the surface) and has an open period of up to a minute during which the parts are mated and, if necessary, held in active alignment. A second burst of UV light fixes the aligned parts; this step is optional if precise alignment is not necessary. Finally, a thermal cure step completes the curing in shaded regions. The thermal cure temperature can be as low as 60-80 °C for 30-60 minutes for thermally sensitive components; for less sensitive components, the thermal cure step can be as short as 5 minutes at 110-120 °C.

dispense activate align fix cure

UV-Snap Cure adhesives are available with either standard flow properties or as thixotropic materials. They offer the typical advantages of epoxy adhesives including high adhesion, low shrinkage, and excellent environmental behavior. For opaque or UV-blocking materials, they provide much shorter cure times than two-part epoxies and lower cure temperatures than thermal cure acrylates. The cured materials have high Tg and a wide range of operating temperatures.

See the UV-Snap Cure products page for the products ACW offers. If you wish to discuss how UV-Snap Cure Epoxies might solve your bonding problems, send us an inquiry: CLICK HERE TO CONTACT US.